Mechanical Shock Tst Machine With 50kg payload Performs Half sine 100g 11ms

Mechanical Shock Tst Machine With 50kg payload Performs Half sine 100g 11ms

Product description

SKT series is the best solution in shock machine's to ensure prodcuts such as smartphones,tables.computers and other mobile devices are able to withstand shock. By appling high acceleration to computer parts, smart phones, tables. laptops,cellular phones. and various mobile products to conduct product fragility test.

| Model | HSKT10 | HSKT10M | G-HSKT15 | G-HSKT30 | G-HSKT35 |

| Table Size(mm) | 200 x 250 | 200 x 200 | 250 x 250 | 250 x 250 | 250 x 250 |

Max. Payload (kg) | 10 | 5 | 10 | 10 | 10 |

| Shock Pulse | Half Sine Wave | ||||

| Acceleration Range(G) | 20~2000 | 20~3000g | 20~15000 | 20~30000 | 20~35000 |

| Pulse Duration(ms) | 0.2~18 | 0.1~11 | |||

| Model | SKT30 | SKT50 | SKT100 | SKT200 | SKT300 | SKT600 | SKT1000 | ||

| Table Size (cm) | 40 x 40 | 50 x 60 | 70 x 80 | 100 x 100 | 120 x 120 | 150 x 150 | 200 x 200 | ||

| Max. Specimen Weight(kg) | 30 | 50 | 100 | 200 | 300 | 600 | 1000 | ||

Max. Acceleration (G) | Half Sine | 600 | 600 | 600 | 500 | 500 | 300 | 300 | |

| Saw-tooth | 100 | 100 | 100 | 100 | 100 | 100 | 100 | ||

| Square | 150 | 150 | 150 | 100 | 100 | 100 | |||

Pulse duration (ms) | Half Sine | 30—0.5 | 30~1 | 30~1 | 30~2 | 20~3 | 20~3 | 20~3 | |

| Saw-tooth | 18~6 | 18~6 | 18~6 | 18~6 | 18~6 | 16~6 | 18~6 | ||

| Square | 30~6 | 30~6 | 30~6 | 30~6 | 30~6 | 30~6 | |||

| Controller cabinet dimension(cm) | W55*D50*H80 | ||||||||

| Machine weight(Kg) | 1900 | 2300 | 3200 | 4200 | 8500 | 15500 | 21500 | ||

| Power supply | 3(phase) AC380V 50/60Hz Compressed air 0.5~0.8MPa | ||||||||

| Standards | GB/T2423-2008 GJB1217 GJB360.23 GJB150 GJB548 MIL-STD-202F IEC-68-2-27 MIL-STD-883E MIL-STD-810F ISTA UL | ||||||||

Equipment configuration

| No. | Equipment name | Model | Qty. |

| 1 | Shock tester table | SKT30A | 1 set |

| 2 | Hydraulic lifting mechanism | 1 set | |

| 3 | Controller | SKC-2 | 1 set |

| 4 | Shock measurement device | 1 set | |

| 5 | Sensor | 1 pcs | |

| 6 | Control computer | 1 set | |

| 7 | Waveform generator | Half sine wave/final peak saw tooth wave | 1 set |

| 8 | Safety device | Audible and visual alarm | 1 set |

| 9 | Attached accessories | Tools, clamps/instructions, installation disc, etc. | 1 set |

Purpose of Shock Testing

· The purpose of shock testing is to determine the fragility of products.

· Ruggedness is a desirable product characteristic.

· A certain amount of ruggedness is necessary for the product's proper functioning.

· Manual handling during distribution normally will "exceed" product ruggedness so protective packaging is usually required

· Shock testing can be useful to improve the ruggedness of designs and add value to the product

· Traditional shock fragility testing used SRS techniques because we lacked knowledge of what inputs were likely.

· SRS was well established in architecture and the building industry.

Customer Services

Presales:

- Technical consultation: test method, laboratory planning and suggestion.

- Equipment selection: selection scheme, FAQ.

- Product testing scheme.

In-Sales:

- Customer communication and progress report.

- Guidance for pre-installation preparation, equipment commissioning and test run.

- Calibration (when Third Party’s verification is required).

After-Sales:

- Technical training: operation of equipment, daily maintenance, common fault diagnosis and troubleshooting.

- Scheduled on-site service: Detection of problem as soon as possible in order to eliminate equipment and anthropogenic hazards. This is to ensure long term and stable equipment operation as well as delivery of latest technical information.

- Technical support: special paid services are provided according to customer’s needs.

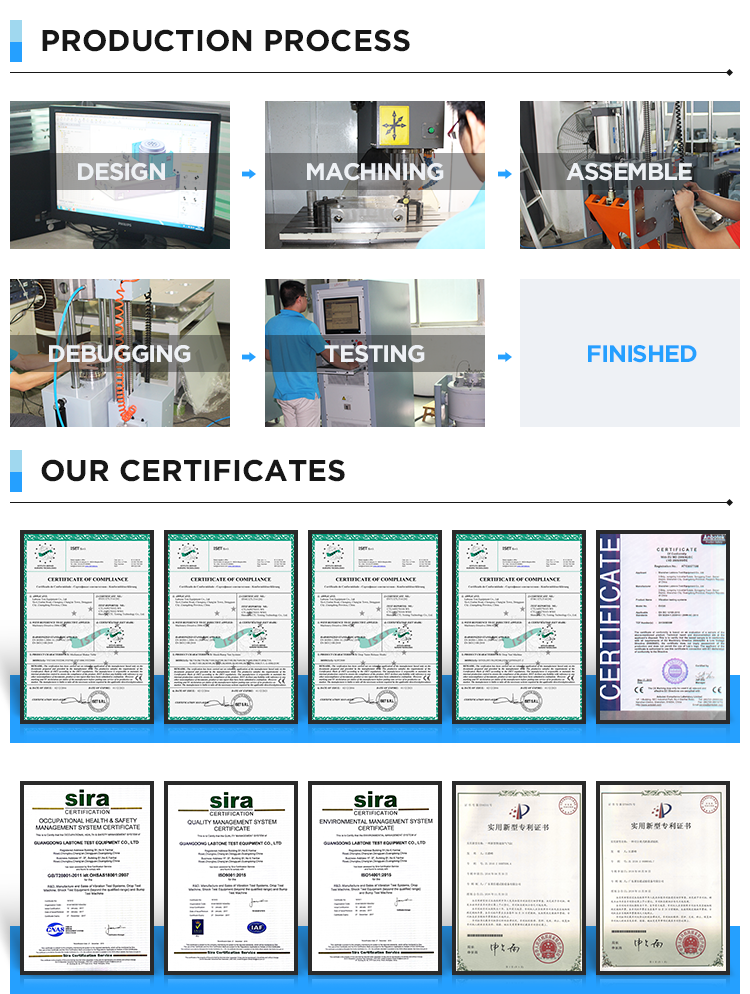

Our workshop :

Labtone Test Equipment Co., Ltd

Labtone Test Equipment Co., Ltd. is a +20 year China manufacture of reliable, cost-effective equipments . Our superior products mainly include: Vibration Test Systems, Shock Test Systems, Bump Test Machine, Drop Tester, Transportation Simulators, Combined Environmental Test Chambers.

Labtone started business in 2002 in a plant located in Shenzhen and moved to our new, expand 6,000 square meter facility in Donguan, GuangDong in 2015.Today, Our products are found around the world in electronics, automotive,automotive,aerospace,telecommunication, optoeletronics instrument and industrial machinery applications. Our experience, and commitment to new product development, has resulted in products that are easy to use,accurate and designed for decades of service

Labtone products carry a one-year(12months) Warranty and are available direct from our factory in Dongguan, China. We provide comprehensive factory service and support,technical literature, manuals and guides as well as having a qualified staff of experts to help solve your application issues.

We sincerely invite you to visit our factory.